As an efficient solution for remote, hard-to-access sites and deposits, the company offers, the "Arctic systems" hangars.

Technical specifications of the "Arctic system" design allow to save the customer’s time and money on transporting it to the site, since it requires but a few containers; also, the reduced mounting time allows to install a hangar for the heavy machinery repair and station within a significantly short period. Our job is to offer the quick and practical solutions , and the efficient and time-saving performance of customer-set tasks in accordance with the European standards and the Russian regulations relative to these constructions.

Along with the new requirements and tasks, our company introduces and integrates the cutting-edge composite materials for quick-mounting constructions. The covering material of the hangar walls and roofs is made of the polyvinyl chloride (PVC) high-tenacity tent fabric produced exclusively in the USA, Germany, and Finland. The tent cover is resistant to negative environmental factors (UV light, temperature changes, precipitation, etc.) This cover durability reaches and exceeds twenty years, providing it is properly used according to the operation manual guidance.

Along with the new requirements and tasks, our company introduces and integrates the cutting-edge composite materials for quick-mounting constructions. The covering material of the hangar walls and roofs is made of the polyvinyl chloride (PVC) high-tenacity tent fabric produced exclusively in the USA, Germany, and Finland. The tent cover is resistant to negative environmental factors (UV light, temperature changes, precipitation, etc.) This cover durability reaches and exceeds twenty years, providing it is properly used according to the operation manual guidance.

According to the fire safety regulations, the combustibility class of hangar materials is G1 by Euro-Asian Council for Standardization Metrology and Certification (GOST) - 30244-94 (does not support combustion, does not form burning drops while heated), the flammability class V2 by GOST 30402-96, and G2 by GOST 30244-94.The tent material is oil-proof, waterproof, and resists temperatures from -30-50 °C (-58°F) to +70 °C (158°F). Tent sheets are welded together by high voltage molecular welding (, which guarantees their structural integrity throughout the product service life.

One of the innovations is a polyvinyl chloride material light transmission, which allows to do without artificial lighting in the daytime, thus reducing electricity expenses in the constructs with only one PVC layer.

One of the innovations is a polyvinyl chloride material light transmission, which allows to do without artificial lighting in the daytime, thus reducing electricity expenses in the constructs with only one PVC layer.

- Single-layer tent covering for a hangar carcass.

- Two-layer covering, consisting of the exterior layer (900 g/m2) and the interior layer (630 g/m2). Between the layers, there is an air gap of 120 to 1200 mm, depending on the construction type.

- Three-layer covering is heat-insulated and has 2 layers of the tent fabric, with the 50 to 100 mm thick heat insulator in between.

The combined covering includes interior walls made of profiled sheets or sandwich panels, and the roof made of the PVC tent fabric..

Quick-mounting hangars do not require official approval, since they are qualified as temporary structures. They are perfect to be mounted on rented spots. The existing line of hangars designed permits to set up facilities from 60 to 3000 m2. The design and engineering services can develop and manufacture various constructs to meet your requirements.

- lower production costs , compared to traditional permanent constructions;

- shortest time for production and mounting - e.g., to fully mount a 1000 sq/m hangar (60×18×10m) takes 30 days;

- mobility - rapid mounting/dismounting possible;

- mounting does not require a sophisticated foundation. Hangars can be mounted over pre-stressed road slabs (PDN) or the standard types of foundation (strip, post, pile);

- demand in the after-market;

- quick-mounting hangars require no intricate equipment, as well as remodeling requires minor financial and labor investments;

- transportations cost by times lower than those for permanent constructions;

- comfort and significant savings in energy consumption, by means of the light transmission PVC fabric.

While calculating the structure of the quick-mounting framed-tent constructs, the building code (SNiP) 2.01.07–85* and SNiP II-23-81* "Steelwork" loads and effects were taken into accounts. The constructions refer to the 4th class of importance; wind and snow tractions are calculated according to the climate regime in the specific installation area.

The metal frame is made of St.3 steel and low-alloyed 09G2S steel, which is galvanized, has a higher point of fluidity, in comparison to the carbon steel, which permits using it for constructions in the North. Bolted-on connections of the frame elements allow the construction multiple mounting and dismounting.

-

Hangar

-

Office

-

Hangar - warehouse

-

Hangar inside

-

Hangar for heavy equipment

-

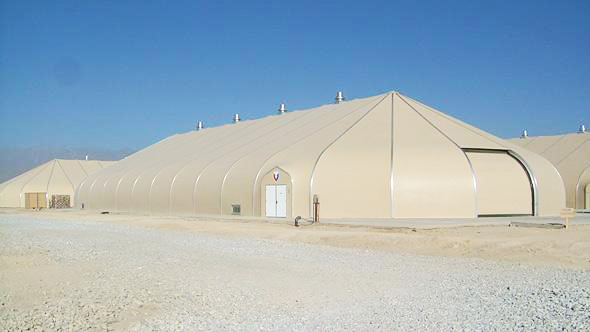

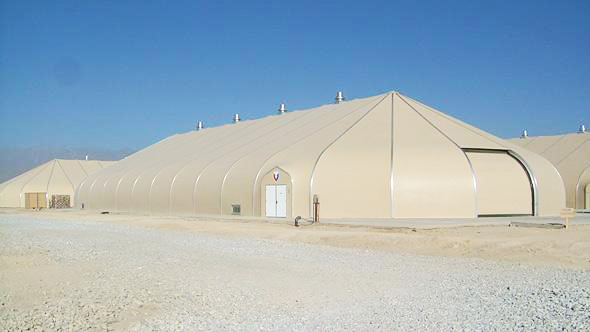

General view of the hangar

-

Hangar - service center

-

-

Window inside

-

Hangars

-

Frame construction

«Arctic System» is an efficient solution for a quick technical arrangement of the site infrastructure, which allows to move it on to the next site at no major expenses, after the previous site has been completely worked out. It is a glance into the future

Our solutions are working for you and your company!

Along with the new requirements and tasks, our company introduces and integrates the cutting-edge composite materials for quick-mounting constructions. The covering material of the hangar walls and roofs is made of the polyvinyl chloride (PVC) high-tenacity tent fabric produced exclusively in the USA, Germany, and Finland. The tent cover is resistant to negative environmental factors (UV light, temperature changes, precipitation, etc.) This cover durability reaches and exceeds twenty years, providing it is properly used according to the operation manual guidance.

Along with the new requirements and tasks, our company introduces and integrates the cutting-edge composite materials for quick-mounting constructions. The covering material of the hangar walls and roofs is made of the polyvinyl chloride (PVC) high-tenacity tent fabric produced exclusively in the USA, Germany, and Finland. The tent cover is resistant to negative environmental factors (UV light, temperature changes, precipitation, etc.) This cover durability reaches and exceeds twenty years, providing it is properly used according to the operation manual guidance. One of the innovations is a polyvinyl chloride material light transmission, which allows to do without artificial lighting in the daytime, thus reducing electricity expenses in the constructs with only one PVC layer.

One of the innovations is a polyvinyl chloride material light transmission, which allows to do without artificial lighting in the daytime, thus reducing electricity expenses in the constructs with only one PVC layer.